Product Description

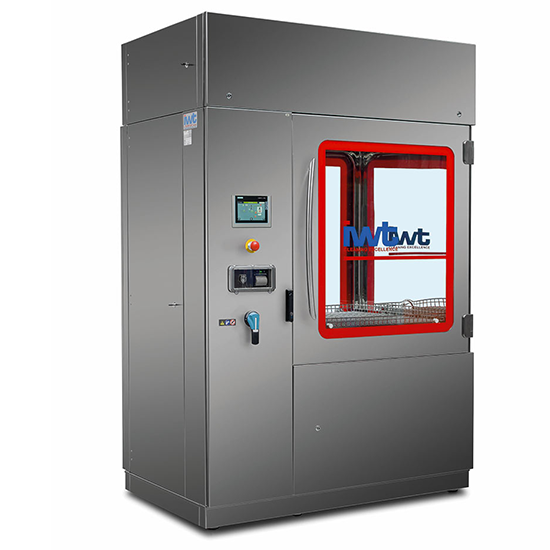

IWT 200EVO cGMP parts washer is designed and built to thoroughly clean pharmaceutical manufacturing components and contact parts. Directly aimed to minimize downtime of product lines and eliminate cross-contamination between batches, the 200EVO surpasses the most stringent cGMP criteria for the validation of your cleaning process.

Fabricated with suitable baskets and racks, standard or custom, this guaranteed placement of items permits repeated alignment for flawless surface coverage and absolute draining. Trolleys, intended for ergonomic operator handling, and storage stands complement this comprehensive solution, optimize process flows and minimize operational footprint restrictions.